Electrifying Tractors

Jack Morrison, from Scythe Robotics, made a post on LinkedIn talking about the electrification of tractors and how autonomous systems can aid in the process. I have thought about this topic for years and decided to do an entire blog post on Tractor Electrification and Autonomous Farming. I love what his team is doing and think the vision of small fleets of autonomous tractors is the future, but I wanted to outline some of the challenges this segment of vehicle electrification will have. Enjoy!

Introduction

Farming itself can be environmentally intensive. My Grandfather likes to talk about the fact he was doing no-tilling before it was cool. So much so that MSU came up to study his farming techniques; I only mention that the Schmidt Farms have always been open to environmental improvements.

As has been established many times1, the operations taking place in farming directly influence climate change, as agriculture has been said to be a “significant contributor to anthropogenic global warming”. The meme around bovine fluctuation is low-hanging fruit, but the truth is that the efficiency of farming has lifted many from hunger and poverty. It is a modern miracle how many people a small number of farmers can feed.

For better or worse, Elon Musk has connected EVs with autonomous driving. The tractors on the farm currently can drive themselves along a GPS track outlined the first time by my Uncle. After he engages the GPS in the field, the tractor will take care of most of the rest outside turnarounds. Given how long Schmidts have been farming here, I am sure the tramlines could be done with eyes closed, but it doesn’t hurt if their eyes are closed.

Where are we?

Though we have made significant strides in the farming equipment currently in use compared to that used just a few decades ago, development and innovation are on a continuum, illustrating that we need to continuously assess how efficient our current methods are and whether their ecological impact can be mitigated.

Early steam and gasoline tractors were ill-suited for the majority of farms. Difficult to move around, brokedown often, and overly expensive for most farmers. As with any technology, each iteration brings new advancements. Thankfully Jerome Case, John Deere, and Henry Ford started with steam and continued to innovate.

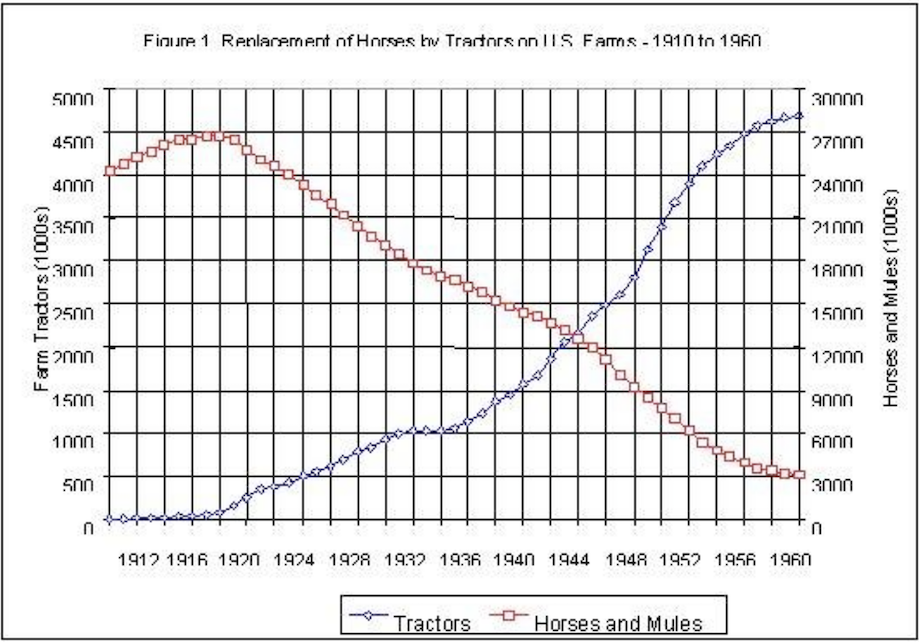

It took 34 years for gasoline-powered tractors to overtake horses. For the longest time, if you look in older newspaper clippings, you’d see farmers joke about how much cheaper and less prone their trusty horses were to break down.

The modern agricultural landscape is unimaginable without the presence of tractors – they are the farm’s workhorses and have single-handedly replaced manual and animal labour in a way that has significantly increased productivity and efficiency.

Yet, we also see that gas-fuelled tractors contribute to climate change through CO2 emissions – something needs to change.

But here’s the fundamental problem. It’s common for tractors to operate up to 18 hours daily during peak harvesting and planting seasons. “Just buy two tractors” doesn’t work practically on smaller family farms where a 3-year-old used combine is still upwards of 400k USD.

Additionally, in our rush to equate EV to Intelligent, we have missed a critical tenant that has royally bit John Deere as of late - Right to Repair. Farmers need to be able to work on their equipment - sometimes as a source of pride, but more often for price and practicality. They can’t simply drive the tractor into town (30+ km) and wait for it to be fixed.

Additionally, in our rush to equate EV to Intelligent, we have missed a critical tenant that has royally bit John Deere as of late - Right to Repair. Farmers need to be able to work on their equipment - sometimes as a source of pride, but more often for price and practicality. They can’t simply drive the tractor into town (30+ km) and wait for it to be fixed.

Currently, the technology available to fuel tractors without fuel simply isn’t cutting it. Specifically, the battery life required to fulfil this need – running a tractor, which is highly energy-costly – is not sufficient. Jack’s post resonated with me because it covers two of the three items on my “triangle of challenges” for tractor electrification. It follows the adage of picking 2 of the 3.

In my mind, you have, for a few quick examples:

- Ability to Complete Job + Battery Life/Charge Time = You have to remove the farmer from the equation so the human resource doesn’t become the constraint

- Battery Life + Need for Operator = Likey cannot complete the planting/harvesting

- Ability to Complete Job + Need for Operator = Battery Life just isn’t there yet

What Can We Do?

So, how do we power machines running 18 hours a day during peak farming seasons?

-

We can consider advancements in battery technology. For example, recent studies2 have shared that “solid-state batteries using lithium metal anodes could deliver a step-change improvement in EV battery range, safety and performance.” In contrast, other studies3 have discussed using aluminium-ion batteries as a “promising alternative to conventional batteries that use scarce and difficult-to-recycle raw materials such as lithium”. This is promising – if we can improve battery life, we can improve the range of operations that can take place without using fossil fuels on our farms.

-

We can consider the development of quick swap battery systems4 which would allow operations to be left uninterrupted, and hence for planting and harvesting to be done continuously without incurring any productivity losses. Essentially, the idea is to ensure that farmers have multiple charged batteries that can quickly be swapped when the battery is depleted. In many cases, the complexity of these sorts of systems can often be a hindrance. Nio with cars and Tier with scooters are showing that it is possible, but it increases the complexity of your device and infrastructure.

-

Autonomy with a reduction in the size/cost of tractors is needed. Many smaller EV tractors being orchestrated by a farmer versus operated by the farmer now expand the hours of the day that can be used and the cost of the devices themselves.

Thinking Ahead

At what point will the advantages of smaller, autonomous tractors outweigh the dominance of traditional and larger machines? Is there a crossover point?

We need to think of this in terms of cost and efficiency parity. Once smaller and autonomous tractors can perform the same tasks as larger ones with comparable or superior efficiency. At a similar or even lower cost, we are likely to see a notable shift towards their adoption. Farmers are pragmatic - once automation benefits – e.g., around-the-clock operation or precision task execution – are clear operational advantages, the switch will happen. And this is where green energy policies must come in. Our government officials must provide incentives to push farmers to adopt this new technology despite its cost – but this is only possible with financial incentives. Farmers already rely on subsidies to keep farms rolling, so there is an abundance of existing regulatory bodies and frameworks to lean on to encourage, train, and deploy this new technology.

We need to think of this in terms of cost and efficiency parity. Once smaller and autonomous tractors can perform the same tasks as larger ones with comparable or superior efficiency. At a similar or even lower cost, we are likely to see a notable shift towards their adoption. Farmers are pragmatic - once automation benefits – e.g., around-the-clock operation or precision task execution – are clear operational advantages, the switch will happen. And this is where green energy policies must come in. Our government officials must provide incentives to push farmers to adopt this new technology despite its cost – but this is only possible with financial incentives. Farmers already rely on subsidies to keep farms rolling, so there is an abundance of existing regulatory bodies and frameworks to lean on to encourage, train, and deploy this new technology.

Given the mindset of many farmers being self-reliant (right-to-repair, hard work, etc.), you can combine that with self-fueling. Charge your fleet of tractors using the sun that grows your crops. It’s a great story.

We still have some work to do, but I am excited about the AgTech space and what is happening. I will miss playing with my daughter and watching my Uncle in the fields next to our house, but I will also enjoy watching them have more time to invest in their personal lives.